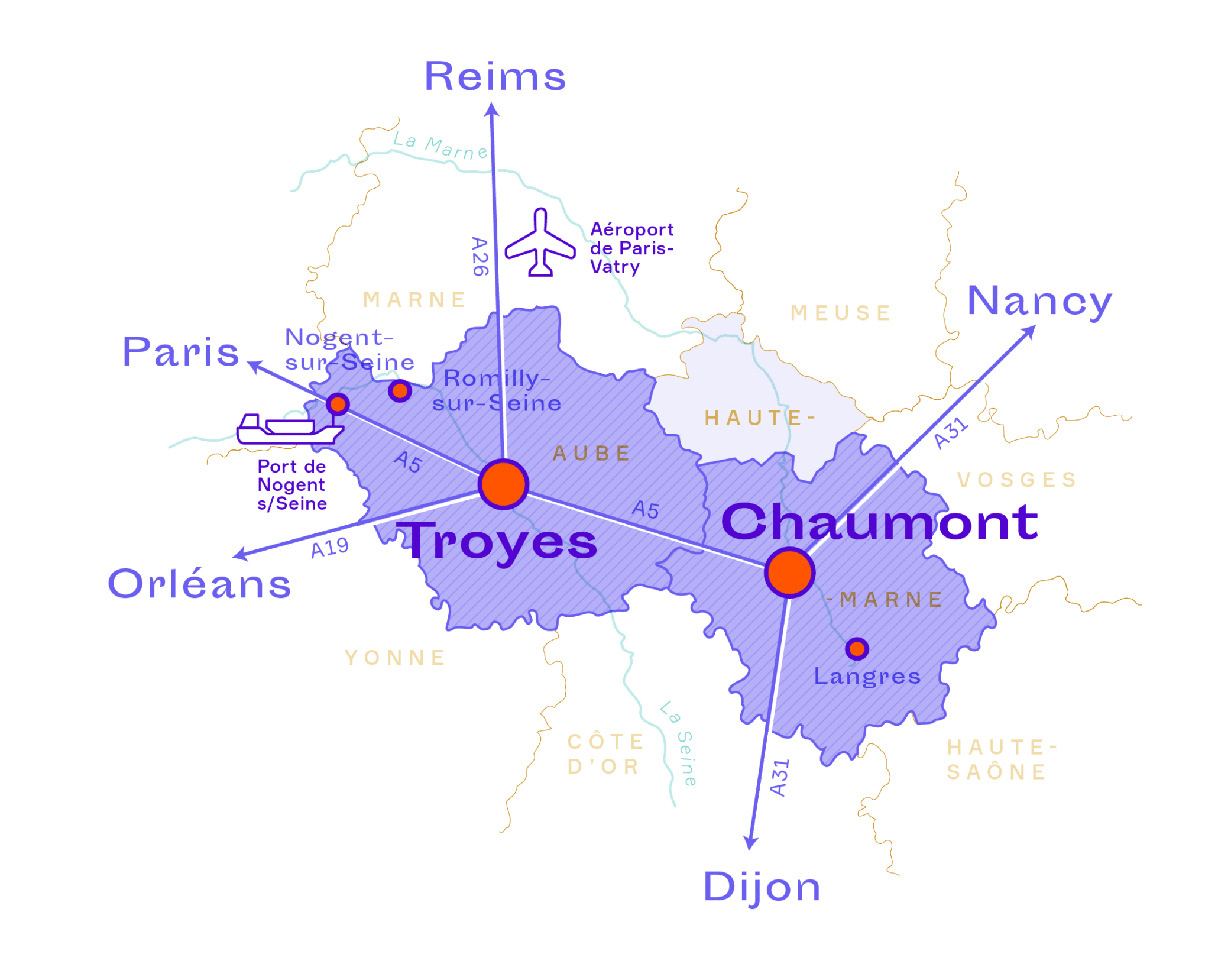

IoT Academy: Garnica’s experience in Troyes

A unique structure in France, specialising in IoT

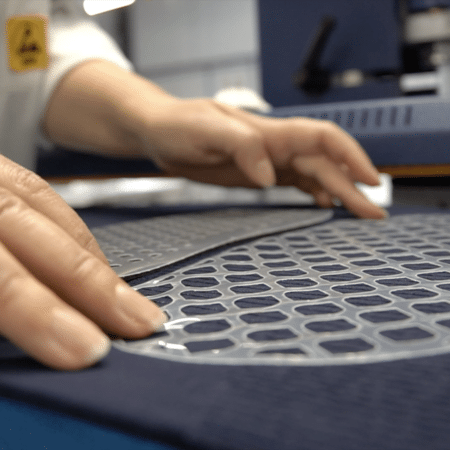

The IoT Academy is an expert in Industry 4.0 and the digital transition. It is located on the Rosières-Près-Troyes campus of the Union des industries et métiers de la métallurgie training centre. It offers training courses from bac +3 to bac +5, supporting companies in the deployment of these new uses and helping to accelerate their digital transformation.

“We create training courses that meet the needs of manufacturers,” explains Michaël Oudin, IoT Academy referent.

In concrete terms, the IoT (internet of connected objects) is used to collect data that can be used to fine-tune predictive maintenance. “This know-how can be adapted to all types of industrial machinery,” emphasises Michaël Oudin. The IoT Academy will soon be expanding to 400 m2. There are also plans to organise breakfasts with manufacturers to explain the benefits of connected objects for their organisations.

The Garnica example

Pierre Dhorne, Director of the new Garnica plant, called on the IoT Academy to make the future Troyes site the Group’s 1st 4.0 plant. The first phase of the study involved an audit of a Garnica plant in Lot-et Garonne, similar to the future Troyes plant. Michaël Oudin carried out an assessment, made recommendations and helped the company to recruit staff and restructure its technical services. In Troyes, Pierre Dhorne was advised on the choices to be made to include 4.0 in the machines he was going to acquire and to equip himself with IoT. He was also assisted with recruitment, with the aim of upgrading the technical department’s skills in 4.0.

Testimony of Pierre Dhorne :

What were your expectations when you contacted the IoT Academy?

The IoT Academy has dual expertise in combining technology and training. This corresponded to the key points of my request: the deployment of tools to improve efficiency and the introduction of training for maintenance and production staff. The solutions proposed had to be practical and applicable in the field.

How did the partnership work?

The audit carried out at the Samazan plant enabled us to anticipate what we needed to take into account during the construction of the Troyes plant, by identifying improvements to be made to the network section through work on Computer Aided Maintenance Management. The IoT Academy also worked with Garnica Troyes’ HR and maintenance managers on staff recruitment and training.

Why build a Factory 4.0?

In practical terms, setting up a 4.0 factory means that malfunctions can be detected at an early stage and remedied quickly by anticipating breakdowns. Predictive maintenance is the big advantage of the IoT. It helps operators in their work: a scheduled 30-minute stoppage is better than a 3-hour stoppage.

What have the UIMM and the IoT Academy done for you?

They listened to what we wanted to do and adapted to our company and our objectives. The aim was not to change everything, but to improve and solve the problems identified at the Samazan plant, which has the same configuration as ours. I’m very satisfied with this experience, because 4.0 may seem complex to grasp, but the IoT Academy has supported me and made me aware of what’s at stake. If there’s one message I’d like to pass on to project leaders, it’s that they should carry out an analysis and work upstream, right from the planning stage, on IoT and 4.0 in general.

What is the future schedule for Garnica in Troyes?

Testing and commissioning of the machines will take place at the beginning of the autumn, with production starting immediately afterwards. The teams will be trained in 4.0 over the coming months. The sensors will be installed so that the first data can be sent back in early 2023. We’re looking for maintenance and production professionals with 4.0 skills or aptitude. If you are interested, please send your application to recrutement.troyes@garnica.one.