When AGC-IVB, the leader in façade glass, decided to supply XXL products “made in France”.

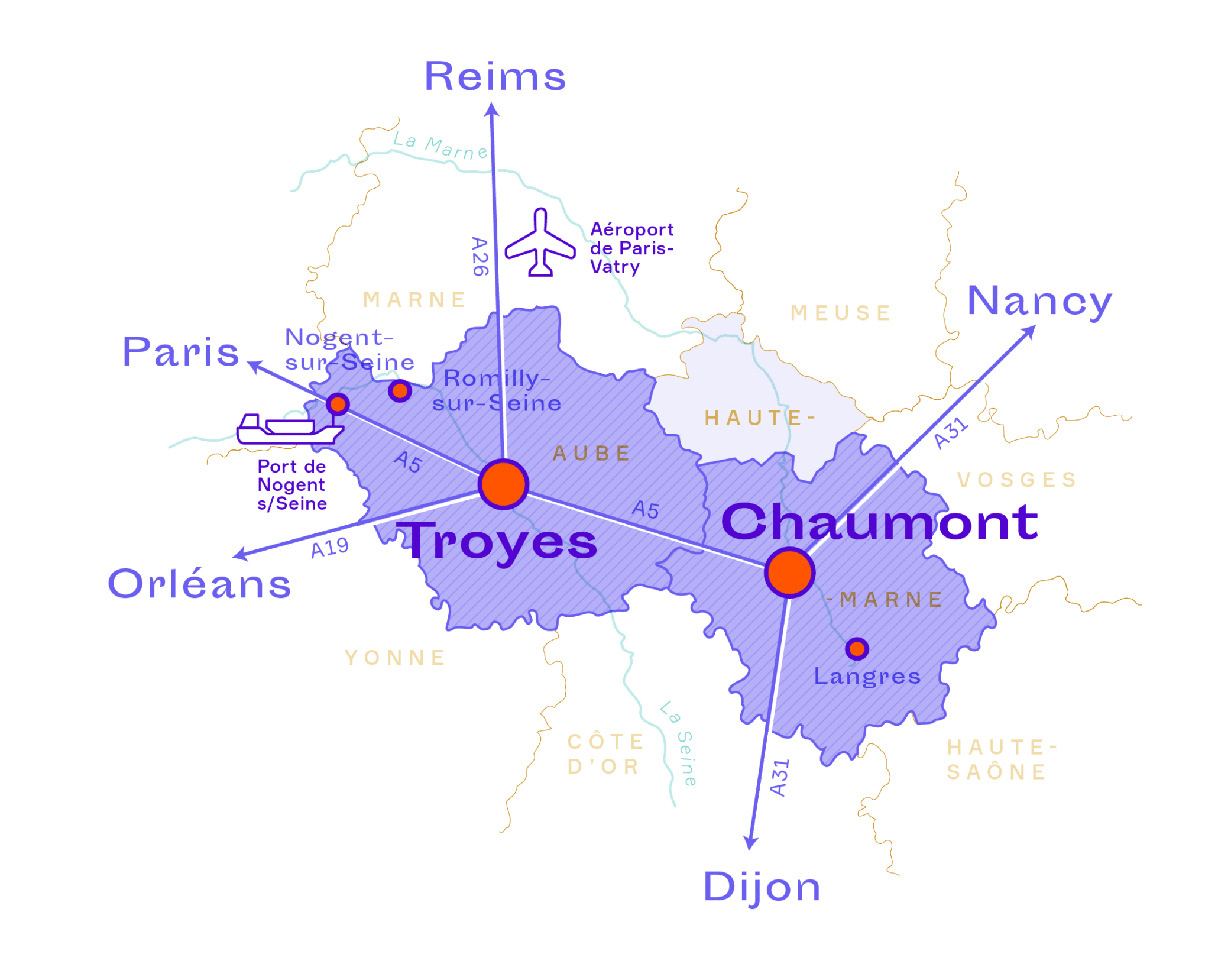

Well-known for supplying complex façade glass, such as the curved glass in the Louvre post office or the 19,000 panes of glass – all different – delivered to Le Monde’s head office, the AGC-IVB site is now pushing back the boundaries of what is possible with a MAXI (6m x 3.21m) technical glazing offer, all from its French site in Troyes – Méry-sur-Seine, 1? hours from Paris.

From double glazing to the supply of complex façade glass

Long gone are the days when the company was one of France’s pioneers in double glazing for windows.

“We abandoned this low added-value standard production 10 years ago for competitive reasons. These products come mainly from Eastern Europe at low prices”, recalls Frédéric Top, Director of the Méry-sur-Seine site. “So we opted for complexity, excellence and market proximity. The façade glass market and the major construction and renovation programmes in Paris were an opportunity for our French site.”

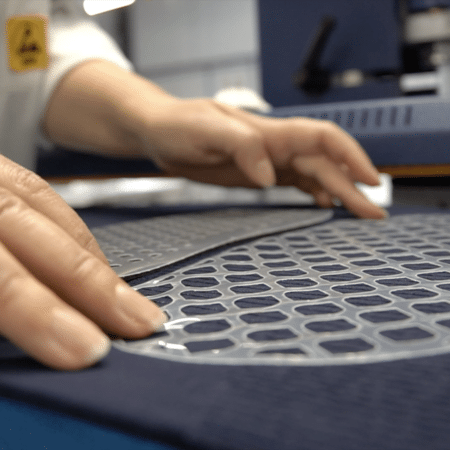

Over the last twenty years or so, façade glass has become an essential element in the construction of commercial and tertiary buildings. The various standards and expectations of investors (safety, thermal insulation, soundproofing, UV filtering, etc.) have led the Aube unit to offer increasingly sophisticated technical and aesthetic solutions. The company now offers more than 300 different solutions, depending on the nature and treatment of the different layers of glass (toughened, laminated, etc.) and the gases injected between them.

Produce and deliver 180,000 m² of façade glass per year

The company, which celebrates its 40th anniversary in 2022, has constantly adapted its designs and modernised its production facilities.

“Our Troyes-Méry site now covers an area of 20,000 m². With a workforce of 120, it has a mechanised in-line organisation incorporating design, cutting, hardening oven, quality testing, screen printing table, assembly table, gassing, etc., which meets current demand in terms of quality and volume,” explains Robert Six, the site’s Technical Director.

Taking all types of product together, the company delivers more than 180,000 m² of façade glass every year. Over the last few years, the company has seen a very significant increase in the number of specific requests from project managers. Each project is unique, and the company has to supply the right product every time, which makes scheduling a constant challenge. The production and delivery of 19,000 different types of glazing for Le Monde’s head office is a good example of the company’s ability to manage complexity.

Invest €4m to go XXL

Always keen to anticipate market needs, the two men have convinced their group to continue investing – more than €4m between 2021 and 2023 – to make AGC IVB’s Aube site the first in France to deliver technical and screen-printed glass for facades in maximum dimensions of 6m x 3.21m (maximum standard size).

“A number of factors led the group to follow our investment recommendations: the site’s industrial and economic performance, our committed and skilled workforce, our proximity to the Paris market – we’re less than an hour and a half from the heart of Paris on the A5 motorway – the advice and support of the Business Sud Champagne economic development agency, and the mobilisation of public funds from the State and the Region during this period of economic stimulus. All we have to do now is gradually integrate all this equipment to become the only supplier of XXL glass ‘made in France’,” concludes Frédéric Top.