Bruno Nahan

© Olivier Frajman

Bruno Nahan, Managing Director of Bugis

Who are you?

My name is Bruno Nahan, and I am the Managing Director of Bugis. We are a company that generates 6 million in turnover, consisting of 27 employees and especially one of the last French manufacturers specializing in soft, knitted materials. We primarily work for the fashion sectors and technical fabrics.

Can you tell us the story of your company?

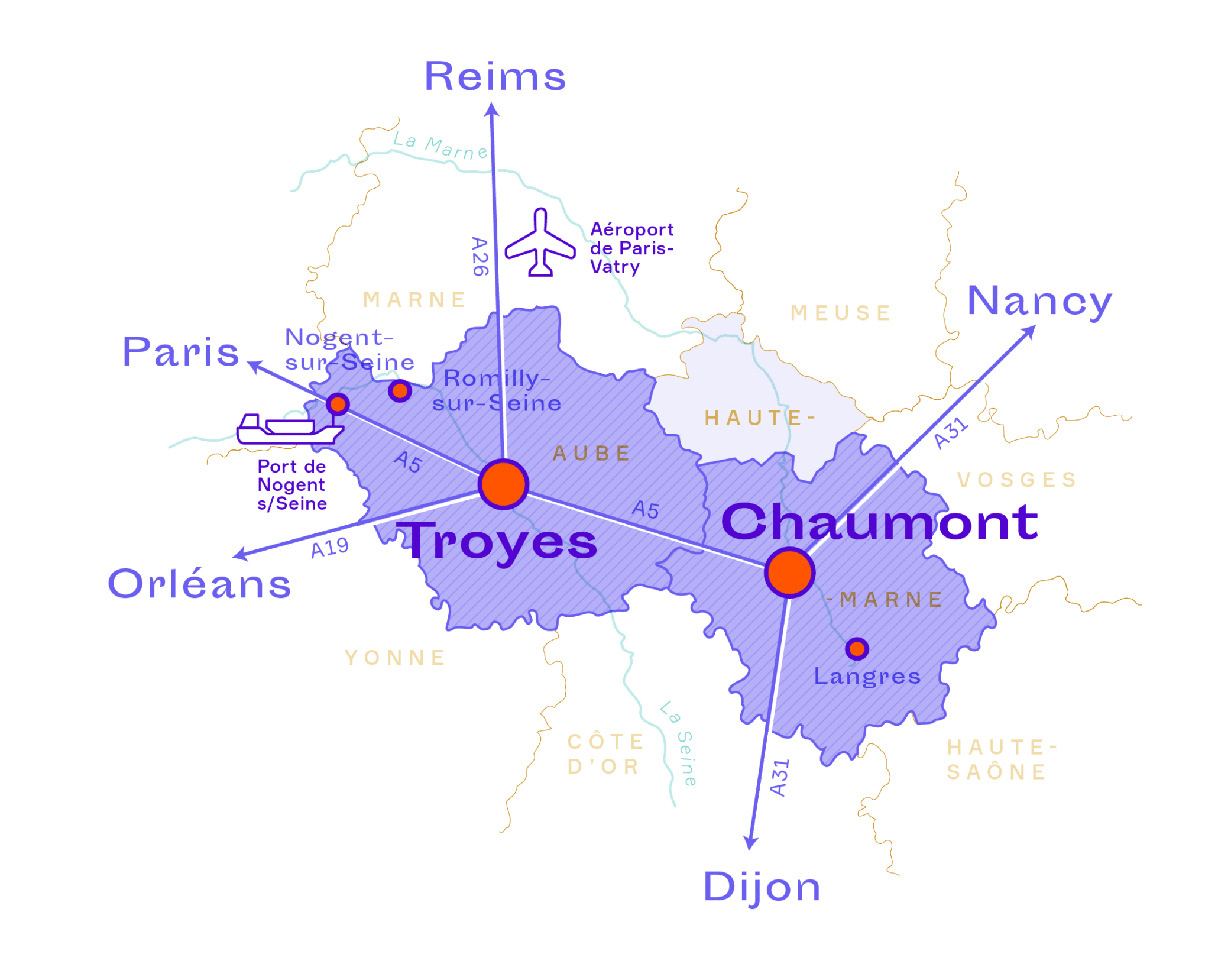

Bugis was founded in 1956 in the Troyes agglomeration, since Troyes is historically the capital of knitwear. The company quickly became a significant player in the manufacture of knit fabrics for the fashion industry. Then, in the 1990s, we expanded into technical fabrics, i.e., all applications related to the use of knit fabrics in industries such as transport, aeronautics, and medical.

What are Bugis’s specialities?

Firstly, Bugis manufactures all of its collections in France, in Troyes. Additionally, we have a long experience with natural fiber materials such as cotton, linen, wool, and fibers derived from wood pulp. In recent years, we have focused on eco-friendly materials, working with organic cotton and recycled fibers. In collaboration with our local partners, we are working on 100% natural dyes without any chemicals.

At what stage(s) of the manufacturing chain do you intervene?

Bugis is an upstream player in the textile sector. We buy raw materials from our partners and suppliers, which we transform by knitting. Then these materials are dyed by our partners present in the local ecosystem. Finally, we deliver to our clients who will carry out the manufacturing of the article for fashion or technical sectors.

Why did you choose the Troyes agglomeration for your company?

For two main reasons. The first is the presence in the South Champagne Territory of a very active sector in manufacturing, finishing, dyeing, lamination, and embroidery. The second reason is the local know-how with teams who master the manufacture of knit fabrics, whether it is design, development, or the operational realization of materials in the workshop.

How did you manage the COVID-19 crisis?

This crisis was an opportunity for the textile sector, which allowed us to show the agility and responsiveness of the local ecosystem as each expertise center worked on the development of masks. Bugis contributed to the filtering and breathable part, and local actors worked on the manufacturing, treatment, and dyeing of these washable masks.

What are Bugis’s future projects?

Bugis has two major projects. The first is to strengthen our position in the eco-friendly fashion market segment and continue to develop natural, organic, recyclable, and 100% Made in France materials like linen and hemp. We also want to continue offering products around 100% natural dyes that ensure the perfect safety of fabrics in contact with the skin for the children’s universe and adult fashion. The second major focus is to continue strengthening our development of breathable and filtering materials for outlets such as medical or industrial applications.