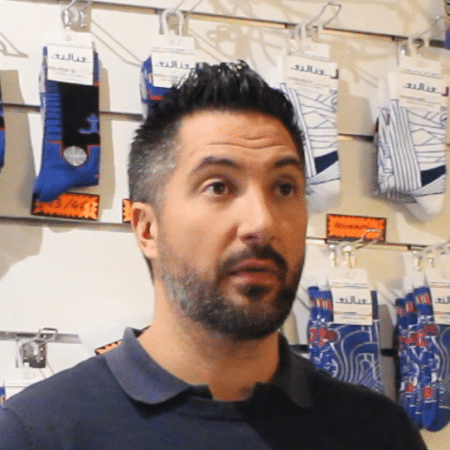

Denis Arnoult

© Olivier Frajman

Denis Arnoult, Co-manager of France Teinture

Who are you?

I’m Denis Arnoult, co-manager of France Teinture since November 2004 and Chairman of the Union des Industries Textiles Champagne-Ardenne since November 2013.

Can you tell us about the history of your company?

As managers at Teinturerie de Champagne, one of Europe’s largest industrial contract dyeing plants, established since 1926 on the current industrial site, Nicola TINELLI and I could not imagine letting the company disappear, a victim of globalisation like many other companies in the textile industry. So on 1 November 2004, we created France Teinture, which took over the assets of Teinturerie de Champagne and 100 employees.

We have been committed to transforming it, with recurring investments, and have always attached vital importance to staff, even during the difficult times we experienced after the 2008-2009 financial crisis, by retaining them in their entirety and working to replace them as and when they retire, in order to ensure the transfer of skills and know-how. This replacement was accompanied by in-house training, in the absence of any external opportunities. As a result, more than 50 people have been taken on and trained in just a few years, while the workforce has been maintained at its original level.

What can you tell us about your company’s business?

France Teinture specialises in dyeing and finishing fabrics of all kinds. Our activity consists of giving colour to these materials, after their preparation, and transforming their visual aspect (apart from colour), tactile and dimensional, as well as giving them, if necessary, properties that they did not have after knitting or weaving. The watchwords of our company are colourfastness and material stability, two guarantees of the quality essential for the use to which these materials will be put.

We work on a very large number of different textile substrates for a wide range of uses, from ready-to-wear to sportswear, from lingerie to sports, from automotive to medical, from furniture to workwear, etc…

As an ICPE (Installation Classée pour la Protection de l’Environnement), we have a duty of strict compliance with environmental standards for our treatments and the products we use to carry them out. This respect applies just as much to the water that is essential to our business, and that we simply borrow, since it is pumped, treated and used for our dyeing baths before being pre-treated and sent to the Troyes Champagne Métropole wastewater treatment plant, which will return it to its natural environment, the Seine, cleaner than when it entered our site, up to 98% of its pumping level.

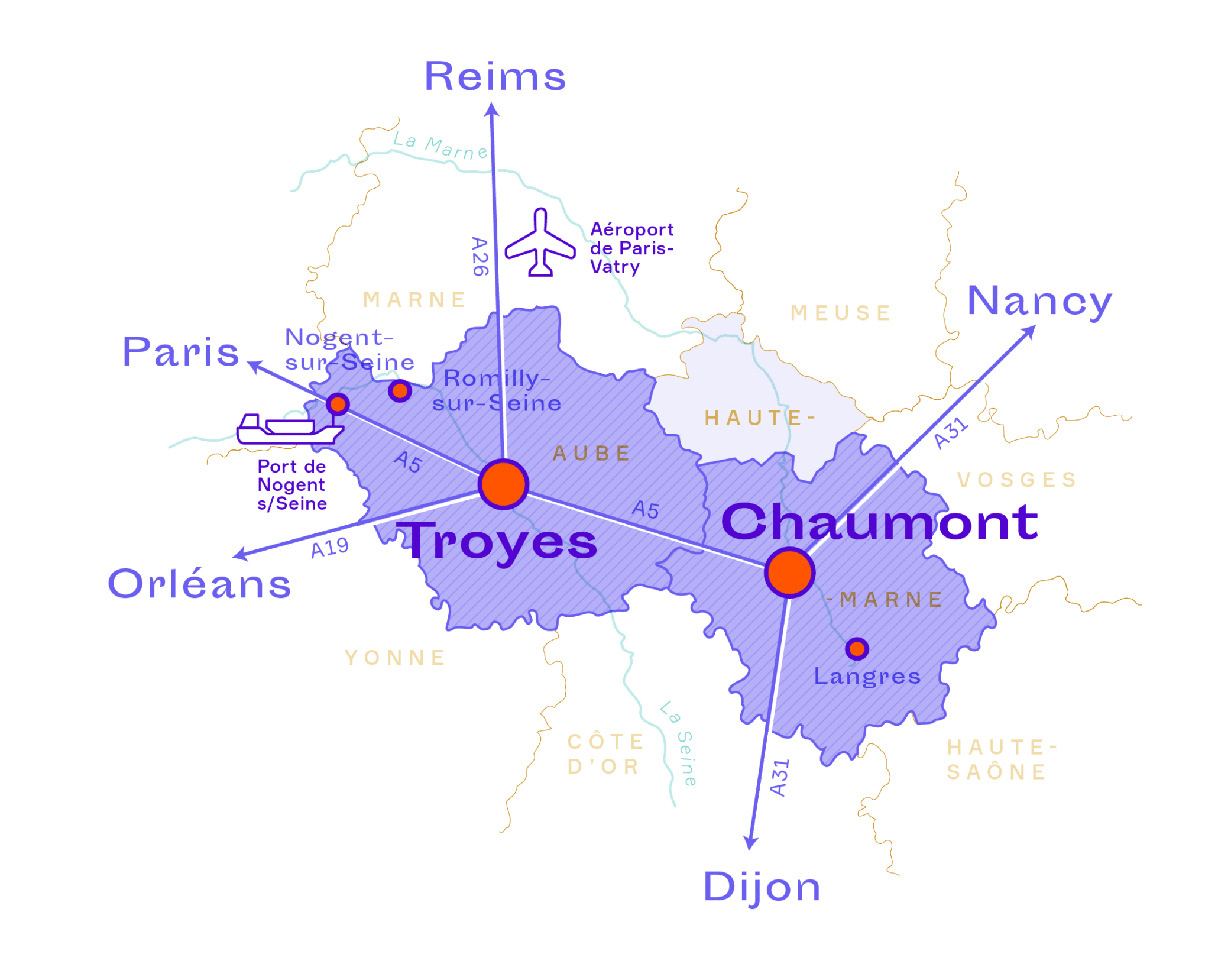

Why did you choose to develop France Teinture in Troyes?

We didn’t choose to develop France Teinture in Troyes, but we did take over an industrial activity that was technically and economically impossible to move. Moving would have meant creating a completely new site, which was not an option.

We therefore set out to rationalise and modernise a work tool consisting of a very large fleet of machines and a heavy industrial infrastructure, specific to the dyeing industry. Our fleet comprises nearly 85 machines, some of them very impressive.

What’s more, Troyes is the historic heart of knitwear in France, and knitwear remains our core business, even if we process all types of materials. And our region has managed to maintain an entire textile industry, starting with knitting, in which our company plays an active role.

How are you coping with the health crisis linked to COVID-19?

Like many companies, we ceased our activity on 18 March until 27 April, when we restarted it with a very small workforce, on a voluntary basis, in order to respond to requests from our customers for orders placed before the stoppage, for fabrics intended for the manufacture of washable masks and, tentatively, for new orders.

This resumption was essential for an activity that cannot be carried out remotely.

As soon as the shutdown was over, all the staff were ready to get back to work, but this was limited by the level of orders and the heavy cloud cover surrounding the sector, a situation that seems to be the rule for the coming weeks and months.

How do you see the post-crisis period?

Out of the shadows and into the light, the French textile industry was able to respond to the immediate needs of the population by mobilising to manufacture washable textile masks, demonstrating its responsiveness and flexibility.

However, after this exceptional period for a production that is just as exceptional, we must hope that the dependence observed for products that are not very elaborate, but are vital, can be the trigger for an awareness of the need to reindustrialise our country to guarantee the independence, quality and safety of all the products that can be manufactured in our country, in parallel with part of the environmental response, by reducing their carbon footprint.

We have a long way to go, and we need to adopt a truly proactive policy that covers all aspects of this crucial issue for our country and the jobs of our fellow citizens.

As far as France Teinture is concerned, we are always keen to listen to the market and to offer our customers treatments to improve the products they market, in compliance with all European regulations.

Locally, we are attentive to the growing importance of the hemp industry and hope to be able to participate in the processing of materials derived from this natural plant, while preserving the fundamental quality that makes it so rich.