Guillaume Bricout

© Olivier Frajman

Guillaume Bricout, Managing Director of Compositex

Who are you?

I am Guillaume Bricout, Managing Director of Compositex. I am 36 years old, married, and have a daughter. I returned to the South Champagne region in 2014, after spending 10 years abroad.

Can you tell us the story of Compositex?

Compositex has been around since 1987. It was bought by the Sotratex group in 1997, then by Christian Bricout in 2007. Since then, it has been a family company which I have had the pleasure of leading since 2019. Compositex specializes in niche markets of technical textiles, initially for manufacturers of orthopedic seats and medical devices. Then, for train seat manufacturers and manufacturers of personal protective equipment like diving suits in the nuclear field.

What is Compositex’s area of expertise?

Compositex works in the design and manufacturing of technical materials. We have soft materials of 350 references, including films, papers, fabrics, foams, membranes, and more. We also have a material library that has been developing for over 30 years, comprising 1500 references produced across Europe. Therefore, we have the capability to offer our clients an assembly of materials that we laminate together to provide “barrier” functionalities like fire protection, waterproofing, and anti-microbial properties. We intervene at the stage of designing the technical material itself before its transformation.

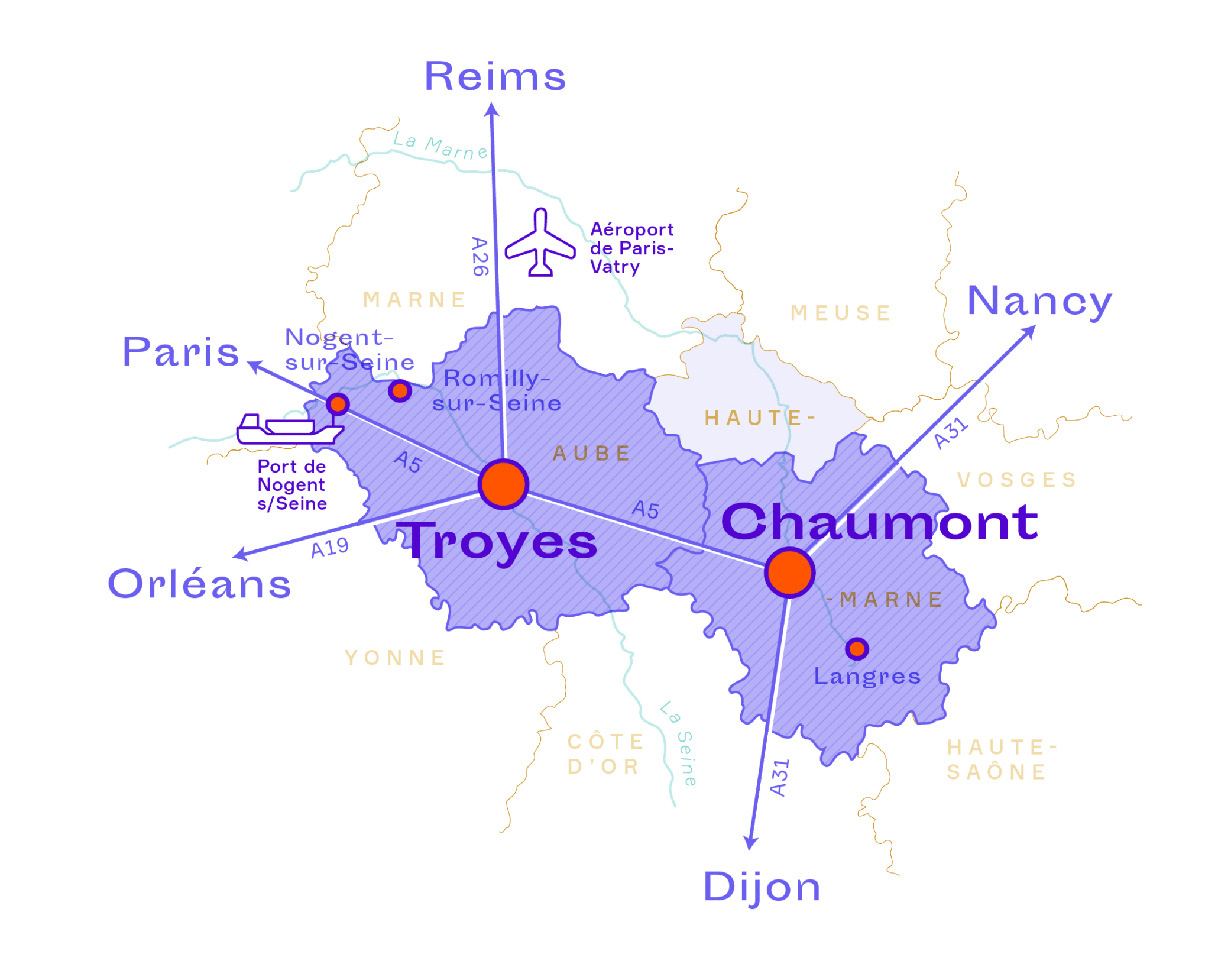

Why choose the Troyes agglomeration for your business?

We bought Compositex, which was already established in the Territory since the company was created simultaneously as the Rosières-près-Troyes industrial area. This positioning allows us today to benefit from local dynamism and work easily with nearby businesses.

What are Compositex’s future projects?

At Compositex, we have two strong focuses: excellence and innovation. Excellence revolves around the standard which we continue to expand the scope of. Innovation involves continuing an investment program. We have invested over 1 million euros in the past three years. Currently, we are relaunching the investment program of a unique lamination machine, custom-made with a combination of different trades that we have selected locally. We also rely on engineers specialized in manufacturing, quality, and processes, as well as on our experience for the realization of this project. This new machine will be delivered in early 2021 and will be dedicated to the production of innovative composites.