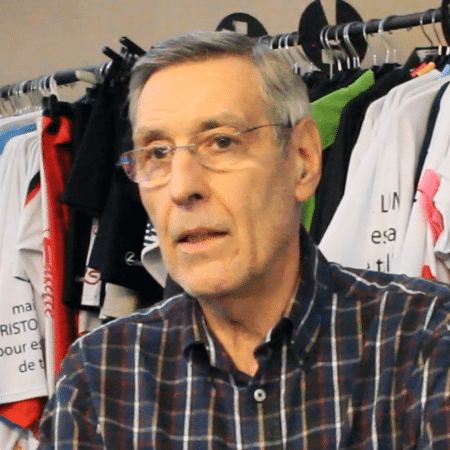

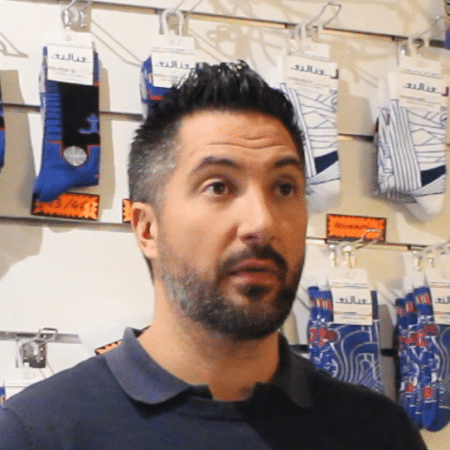

Pierre Dhorne

Pierre DHORNE, Director of Garnica in Troyes

Who are you?

“My name is Pierre Dhorne, I’m a forestry engineer and I’m currently in charge of setting up Garnica’s new plant in Troyes. Eventually, I’ll take over management of the plant.”

Can you tell us about your company?

“Garnica is a family business specialising in the production of poplar-based plywood. It has a turnover of around 250 million euros and produces 300,000 m3 of plywood, mainly for export to Europe, North America and the United States. There are currently 1,100 employees, spread over 6 plants, and the aim is now to build a new plant in Troyes.”

Why did you choose to locate your plant in Troyes?

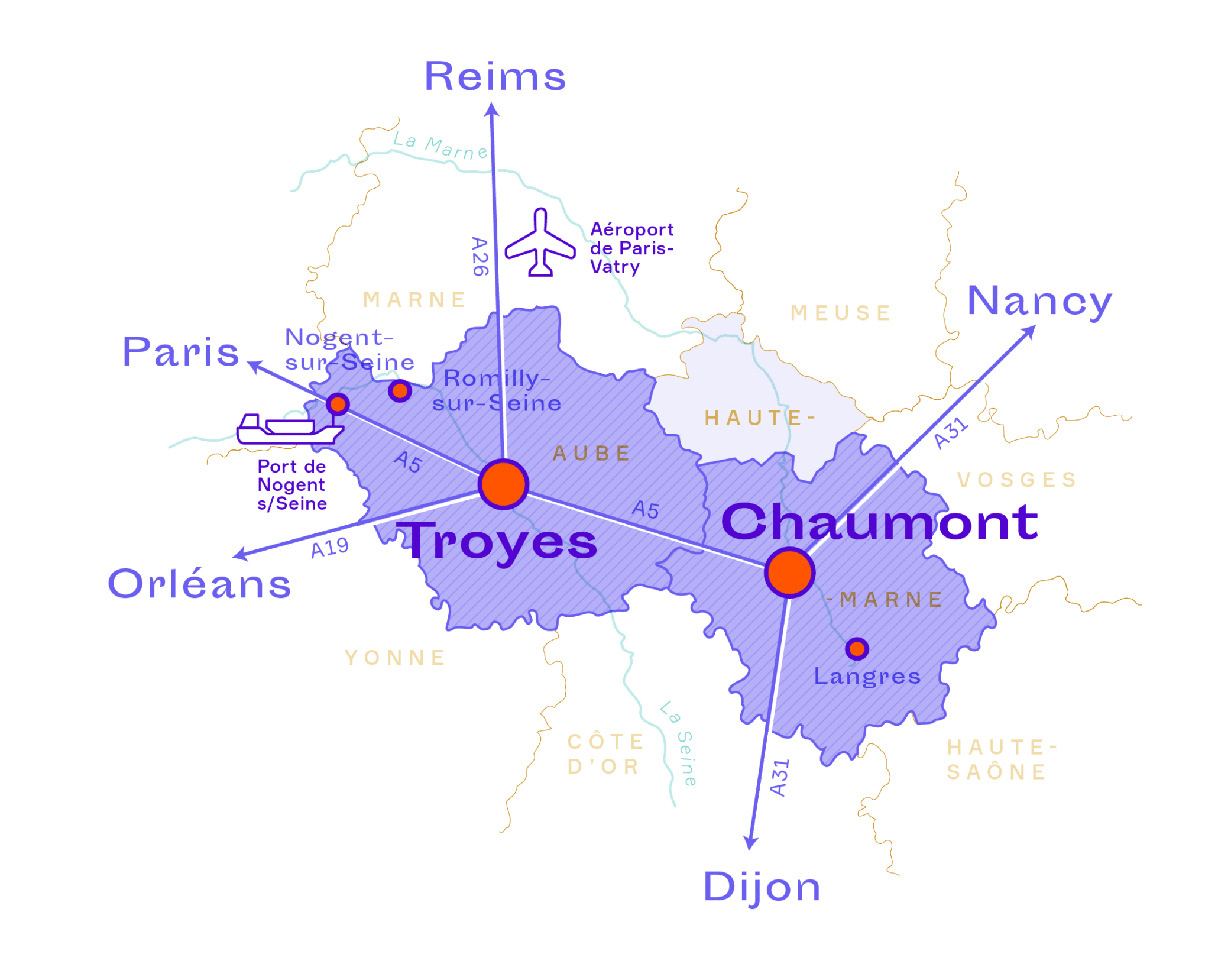

“In addition to the availability of land and our position in relation to the deposits in the Aubagne region, there were 3 factors that set us apart. The first was the industrial culture and the workforce available locally. The second is that Troyes is at the heart of Europe in terms of logistics, particularly for shipping our products. The last important point is that we felt there was a real synergy with the various contacts we had in the area, both public and private institutions. These are all points that enabled us to choose Troyes with confidence.”

How many people are you planning to recruit?

“The ultimate goal is to create 250 to 300 jobs. Initially, we’re starting with around fifty people, with a gradual increase over the life of the project.”

How do you work with local players?

“Excellent. As far as we were concerned, there were two key points that we were looking for from the local players. The first was maintenance, and we worked hard on this with Business Sud Champagne, Troyes Champagne Métropole, the Grand Est region, Pôle Emploi and APEC. This enabled us to define our needs so that we could put in place sourcing and training programmes, and today we can see from the first recruitments that the region is attractive, which has enabled us to get our project off the ground very quickly. The second element concerns the forestry profiles, where there was exactly the same dynamic of exchange and speed, to best meet the company’s needs.”