Thomas Delise

Thomas Delise, Founder of the Elacio brand

Who are you?

“My name is Thomas Delise, I’m 31 years old and I’m the current chairman of Chanteclair hosiery, a company I bought 2 years ago and which has been in existence since 1973. It’s a family-run textile company specialising in knitwear, and it’s in its factory that we’re developing the Elacio brand”.

Can you tell us about your brand?

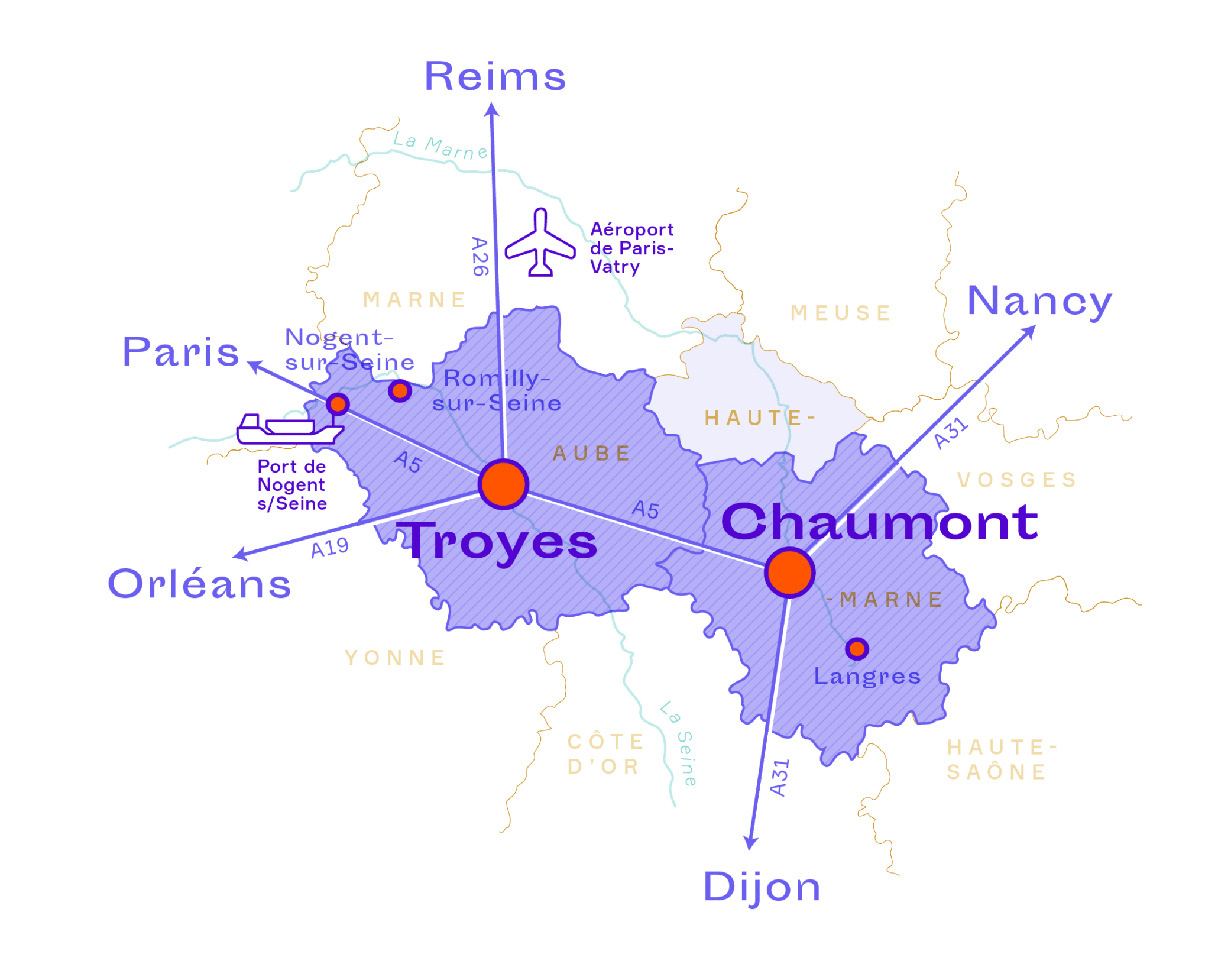

“Elacio is a ready-to-wear brand 100% assembled in France, more specifically in Troyes, and which was created in 2019. Its name means “transport of the soul” in Latin, because 35 people assemble an Elacio product in our Chanteclair factory in Troyes. There are also dyers, spinners, knitters and manufacturers of raw materials, all working in France. In total, more than 80 people work to make our products. Le transport de l’âme brings all these people together under a single brand: Elacio”.

How did your vocation as an entrepreneur come about?

“First of all, I’d like to say that I currently have a fantastic job. I’m the chairman of a company employing 35 people and I’m the creator of the Elacio brand. This vocation came to me following an observation I made about the current ready-to-wear market. Every time I looked for a good product, I’d come across either beautiful finishes but poor materials or beautiful materials but poor finishes, but I could never find the perfect product. One day, I had the chance to take over a family business, so I seized this opportunity to offer textile products that suited me and above all to allow a Made in France know-how to endure”.

Why did you choose to focus on knitwear?

“Chanteclair hosiery has specialised in knitwear since 1973. We make jersey, pique and other knitted fabrics. Elacio is therefore exploiting this know-how to offer different products that are not usually made in knitwear.”

What stages of the production chain do you master?

“We’re mainly involved in the manufacturing process, because Chanteclair is a clothing factory. However, we also carry out the entire manufacturing process, from the yarn to the finished product, including of course the raw materials, for which we rely on French knitters.”

Why did you choose to produce your brand in Troyes?

“I think it makes sense, because today’s consumers want to be closer to home, with fewer journeys and more transparency about the products and how they are made. All of which we can prove by manufacturing here. What’s more, Troyes is the former capital of the textile industry. Historically, the town accounted for over 60% of knitwear production in France. Some of the greatest kings and queens even came to Troyes to get their stockings, so the town has a great deal of historical know-how. Every family in Troyes has at least one parent or grandparent who worked in textiles. This expertise is still there, so I think it’s the place to be if you want to make a textile product. Especially as Troyes is home to the entire garment manufacturing chain, from dyers and knitters to garment makers.”

What are your plans for the future?

“The first important point for the future is to raise Elacio’s profile, as it is still a young brand with everything to prove. The brand also aims to modernise our factory while retaining existing expertise. My second objective is to bring new people into the factory, and so pass on the know-how of the 35 employees already here. The final objective is to enable young designers to come and work with us or even collaborate with artists on our products. Ultimately, we want to enable the younger generation to have an impact on our products by bringing us their vision of the textile world.”